Moisture Sensor calibration

Moisture Sensor calibration is critical to successful moisture control. If either the wet or dry Sensor calibration is 1% off, the control will not act in a proportional and rational manner. Take samples of both incoming and discharge grain. Calibrate three (3) times a day or more until you are convinced the sensors are tracking properly. Then calibrate three (3) times a day for peace-of-mind.

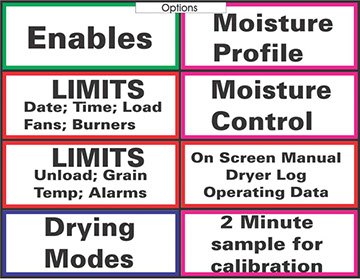

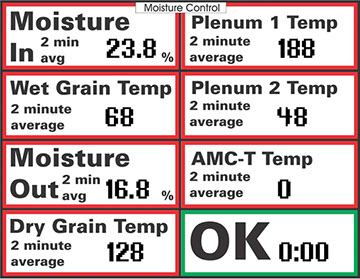

Follow specific directions in your QUANTUM® Manual, on the instructional CD and on the QUANTUM® screens. See screens at right.

- 1. Press the “2 Minute sample for calibration” button. The QUANTUM® is set to use a two-minute sample procedure. This time length will ensure a representative sample.

- 2. Collect samples from the wet and/or dry grain.

- Wet samples:

- MEYER®-S and BCT Tower Dryers: The wet grain sample is obtained using a lever mounted to the Leg Weldments.

- SQ Dryers: The wet grain sample is obtained using a lever mounted on the rear bulkhead of the Dryer.

- Dry samples:

- MEYER®-S and BCT Tower Dryers: The dry sample must be obtained between the Dryer discharge and the elevating leg as installed by the customer.

- SQ Dryers: The dry sample port is located on the bottom of the dry conveyor just before the grain exits the conveyor.

- 3. Obtain a uniform grain sample by collecting eight (8) 1-cup samples of grain at fifteen (15)-second intervals. Mix the collected sample for an accurate test.

- 4. Test the grain sample’s moisture and temperature using a reliable bench moisture tester.

- 5. Enter testing results into the QUANTUM® OFFSET screens to complete the calibration procedure. Note: It will take five (5) calibrations to make a complete offset correction.

QUANTUM® Offset Screens

Copyright © 2014-2016 CTB, Inc. All rights reserved BLV0216