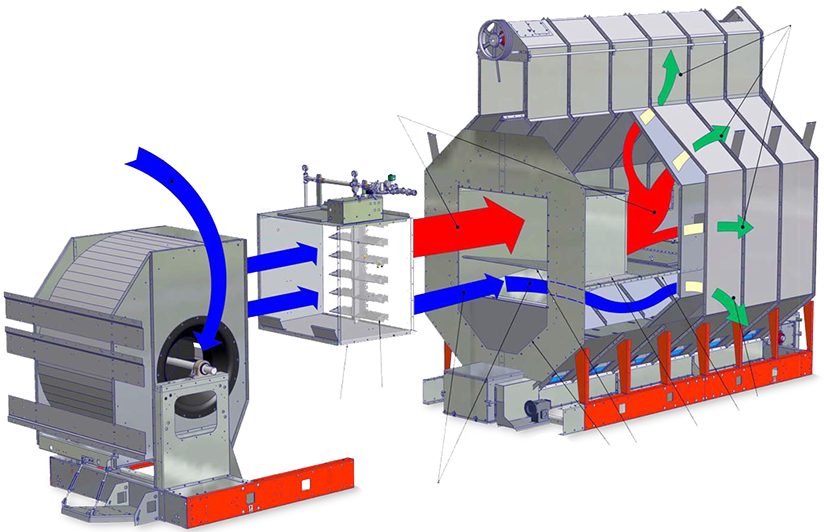

DRYING MODE FOUR:

PRESSURE HEAT and PRESSURE COOL - Two Zone (M, E or A Models)

Pressure Heat / Pressure Cool - Two Zone mode (SQM, SQE, and SQA models) is by far the least efficient mode of drying and the most thermal shock to the grain. However, it is necessary to cool grain before it goes to a bin without aeration. SQD and SQM Dryers are not equipped with return air ducting and not able to vacuum cool grain and reclaim the energy in the hot grain. An SQD model must dry grain as a batch to be able to cool it before sending it to the bin. Another purpose of pressure heat / pressure cooling is for volatile grains such as sunflowers or milo. Vacuum cooling would potentially recycle flammable material into the Dryer.

Rollover info balloon.

1. Blower

2. Fresh Air (Ambient)

3. Heated Drying Air

4. Drying Exhaust Air

5. Internal Air Duct

6. Transition

7. Burner (inside Transition)

8. Air Splitter Door (bottom Duct piece) in UPPER position

9. Return Air Door in LOWER position

10. Plenum Floor

11. Cooling Air (Ambient) bottom

1/3 of Burner is OFF

12. Cooling Exhaust Air

1

2

3

4

5

6

7

8

9

10

11

12

Copyright © 2014-2016 CTB, Inc. All rights reserved BLV0915