Monitor Dryer Activity On A Regular Basis.

Monitor Dryer Activity On A Regular Basis.

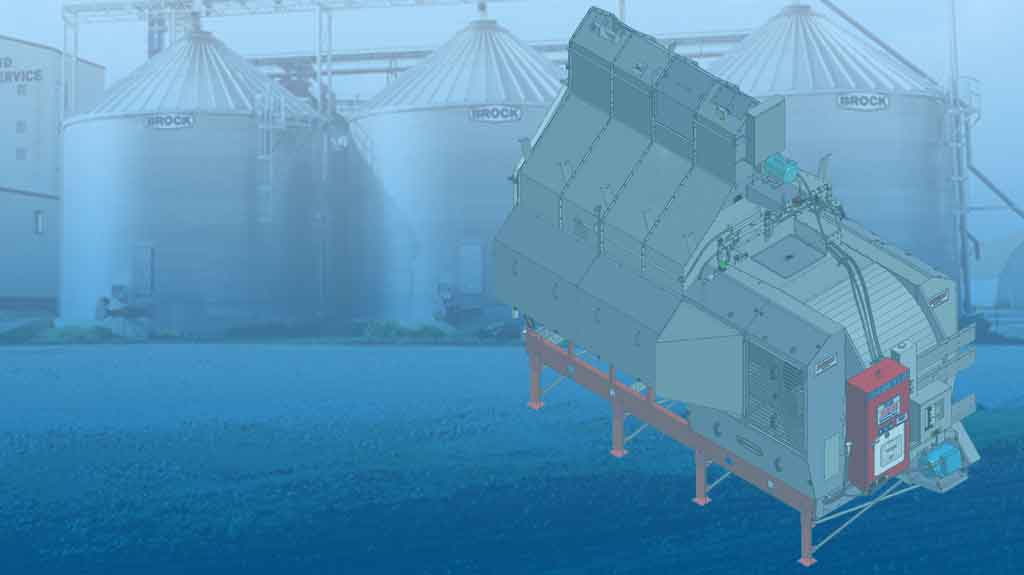

Dryer Location Is Important in the Event of Fire

Plan and evaluate the location of the Dryer and nearby SAFETY equipment to minimize a fire hazard and to be prepared in case of emergency.

- Install Dryers upstream of area dust sources (unload pits, etc.). Install dust management devices that reduce dust in grain-handling facilities. Locate the Dryer where combustible material will not be easily drawn into it. Manage incoming grain with aeration.

- Maintain an absolute minimum 8’ [2.438 m] clearance between the Dryer and any surrounding structures or obstructions. Where there could be heat buildup, do not store fertilizer or other flammables.

- Operators should take care not to steer movable equipment in proximity with the Dryer area or combustible propane tanks. Do not block emergency vehicle access to the Dryer or tank(s).

- Propane tanks, if struck and damaged, may result in injury and/or fire. Store LP tanks on level ground capable of supporting their maximum full weight. Follow local LP suppliers' codes for tank placement and recommended distances away from the Dryer.

Emergency Preparedness and Prevention

- Purchase and keep ABC or carbon dioxide (CO2) fire extinguishers nearby and ready. Instruct all personnel how to properly use them. A fire extinguisher may be useful for a small fire near the pad.

- Install and maintain a water source nearby. If your facility is in town, check for the nearest fire hydrant.

- Enforce a NO SMOKING policy on the premises. Ideally there should be no smoking within 50 feet [15.24 m] of any grain facility. Follow all local smoking ordinances, which may entirely prohibit smoking in public places.

- Enforce a NO SMOKING policy on the premises. Ideally there should be no smoking within 50 feet [15.24 m] of any grain facility. Follow all local smoking ordinances, which may entirely prohibit smoking in public places.

- DO NOT OPERATE the Dryer while the LP tank is being filled—wait for ten minutes after the truck filler hose has been removed.

Develop and practice emergency procedures and fire drills.

Dryer Maintenance Reduces Fire Risk

Make periodic inspections of the Dryer as described in the Preventive Maintenance section on the Quantum H2M.

- Inspect to make sure the Burner holes are clean and clear.

- Check and service the Burner and other components before the drying season. Use a wire brush, tip cleaner and vacuum to service the Burner to open all the holes and remove any rust or debris.

- Check solenoids for leaks and gauges for proper operating pressure.

Copyright © 2014-2016 CTB, Inc. All rights reserved BL0815