Preventive Maintenance Schedule

IMPORTANT! The following are MINIMUM maintenance requirements:

Daily (assuming 24-hour-per-day operation during drying season)

- Clean foreign material from the Fan Inlet Guards.

- Sweep off the top exhaust slope where fines have accumulated on outer perforated skins.

- Visually check for uniform grain movement along all perforated panels of the lower outer grain column slope. Pay particular attention to the area directly under the Wet Grain Hopper where excessive amounts of fines and foreign material can accumulate.

- Check the grain supply for chunks of frozen material in cold weather which may wedge a conveyor, causing a Belt burnout, chain breakage, or a Motor overload shutdown.

Semi-Weekly: Shut down for cleaning

- Check inner perforated skin panels for dust and chaff accumulation (especially if grain has excessive foreign material). Sweep down if necessary and remove mate- rial from inside the Dryer.

- Through an open panel, sweep fines and chaff accumulated on top of the Unload Cover, down into the Unload. Check Drag Cover Access Panels, to be sure a proper seal is maintained.

- Replace all Covers and Guards.

Weekly

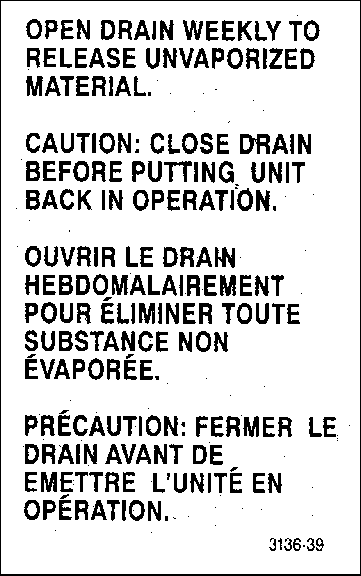

Inspect the Plumbing Train. Drain the drip-leg on LP-gas model Dryers. Use pipe joint compound on pipe threads when replacing the plug or cap. It may be necessary to clean these each week or more often, as fuel quality in some areas is poor. Check for and correct gas leaks around plumbing fittings, especially on high-pressure Vaporizer lines.

Inspect the Plumbing Train. Drain the drip-leg on LP-gas model Dryers. Use pipe joint compound on pipe threads when replacing the plug or cap. It may be necessary to clean these each week or more often, as fuel quality in some areas is poor. Check for and correct gas leaks around plumbing fittings, especially on high-pressure Vaporizer lines.

Semi-Monthly

Unload and clean grain completely from the Dryer. Thoroughly inspect grain columns for accumulation of trash and fines, especially at the peak of the inner perforated grain walls. If grain columns are excessively trashy, clean as described above for Weekly.

Remove trash from the grain before drying. Check tension and condition of the V-Belts on the Fan, Load Auger. Tighten Belts if necessary by moving Motor Mounts and adjusting all Bolts equally. Motor Base Adjustment Bolts are located on the right-side lower frame of the Dryer. Adjust both Bolts uniformly to maintain correct Motor alignment, Belt tension and wear.

Fan Belts should never squeal at startup. if they do, they need to be cleaned and/or tightened. See the “SQ Belt Tension Chart”

Chain Tension Adjustment Bolt at

Rear Discharge

1

2

Motor Adjustment Bolt at

Unload Motor

2

3

Continue

Copyright © 2014-2016 CTB, Inc. All rights reserved BLV0915