Monthly (all year round)

Run the Fan and Load Auger and Dry Conveyor for about ten (10) minutes once each month to keep a protective lubricant film on bearings, gears and chains.

End-of-Season

- Unload grain from the Dryer and check columns for complete removal.

- Sweep off the inside and outside perforated skins

- Clean off all material resting on the Unload Service Access Doors.

- Close all Service Access Doors.

- Wash down the Dryer inside and out (optional). Avoid getting water in the Burner or Fan Motor by covering them with plastic. When finished washing, remove the plastic sheets and fire the Dryer at a low plenum temperature until all parts are dry.

- Cover the Fan, Load, Unload and Auxiliary Motors. To prevent moisture condensation on the Motor, provide for ventilation.

Pre-Season Maintenance (and annually thereafter)

Plan well in advance in case repairs or parts are needed. Carefully perform and combine all procedures listed under Daily, Semi-Weekly and Semi-Monthly as the annual maintenance routine.

Clean out all accumulated foreign material and fines from the Dryer plenum, grain columns, and around the Fan. The OSHA Grain Handling Standard 1910.272 (j) requires a grain facility owner or employer to develop and implement a written housekeeping program that identifies high-dust-collecting areas and:

- the methods by which “fugitive grain dust” will be eliminated from exposed surfaces such as ledges, floors, and other equipment;

- establishes how often the cleaning will be done;

- documents in writing that the above cleaning has been done properly.

Do a SAFETY check.

- Check for missing and damaged DANGER, WARNING or CAUTION Safety Decals. Obtain replacements if required.

- Perform all Safety System Checkout instructions. See Main Menu.

Check all non-moving parts: Panels, Doors and Guards for tightness of fit, and to see they are not touching Belts. Examine all rubber hoses and gaskets and replace as needed.

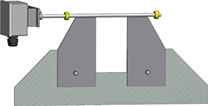

The Top Grain Level Switch (or TGL) is a mercury switch connected to the paddle that is hanging vertically beside the wet fill auger. In this position the contacts are closed, starting the Load On Delay Timer. As the paddle is rotated counter- clockwise either by hand or grain flow, the TGL opens to stop the fill auger.

Continue

Copyright © 2014-2016 CTB, Inc. All rights reserved BLV0915